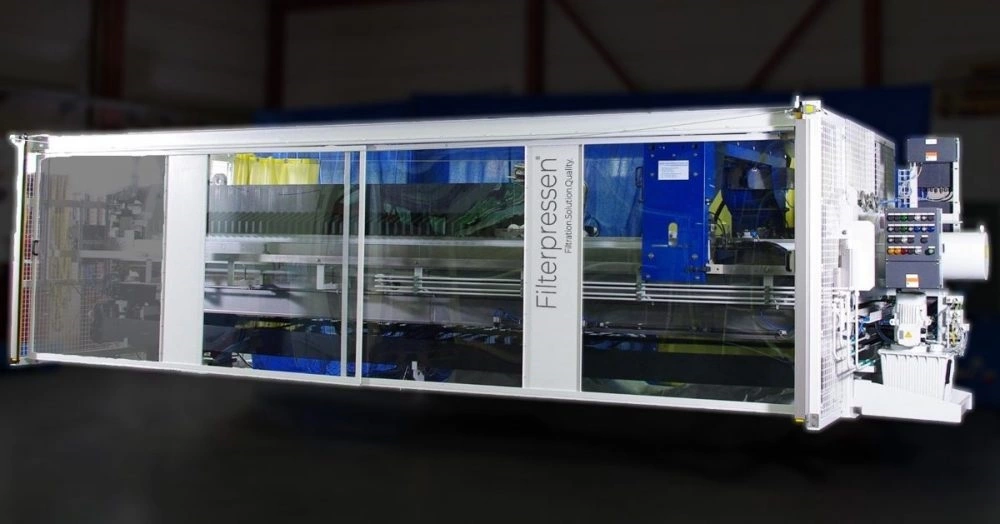

1. Completely automatic control.From feeding to discharging, it adopts unattended operation.

2. Aopts Siemens PLC. It can recognize remote operation using Ethernet.

3. Integrated with different functions to boost the performance and also saves labor expense.

4. The cabinet elements make use of worldwide renowned brand to ensure that secure working as well as easier for future maintenance.

5. Filter plates is membrane type. Additional pressing can obtain the lowest residual cake dampness.

6. Various safety and security control very enhance the safety and security quality.

Features & Specification

Nowadays, the membrane layer filter press is the market pattern. In China, membrane filter press additionally is called chamber membrane layer filter press. Because its plate pack consists of chamber filter plates and membrane layer filter plates. fully automatic filter press For chamber plates, it’s made use of to save filter cakes, because it has deepness. Nevertheless, the surface area of the membrane plate is level. It has 3 layers and also is hollow. So its feature is only for cake squeezing to obtain the very best filtering system efficiency. Detail membrane layer squeezing principle please check the animation online.

For some superior need, consumers want numerous features to fulfill their filtering technological needs. Those adaptable features mainly include Belt Conveyor, Drip Tray (Bomb Door), Cloth Washing System, Plate Shaking System, Vehicle-mounted Device, Light Curtain, Fast Open Device, etc. They not just save labor price but also significantly enhance the filtration effectiveness. Of course, the above products, likewise are suitable for automated chamber filter presses. Please call us for individual design and also solutions.